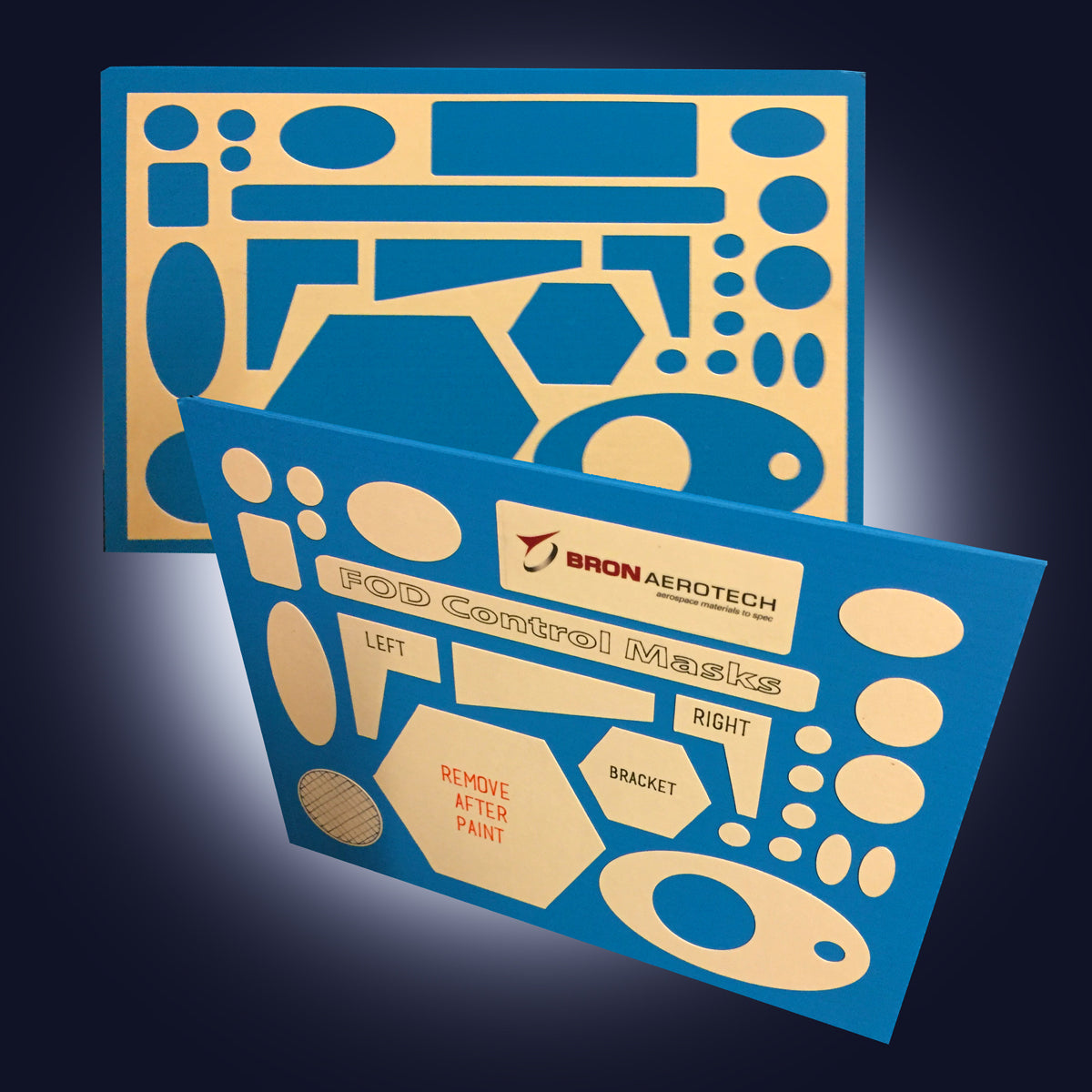

BA FOD Control Board Kit

Bron Aerotech FOD Control Boards supply individually- shaped, kitted aircraft tape maskants for use in the paint/assembly process. Each kit is custom-designed to meet the build requirements for each ship set. The BA FOD Control Board utilizes a shape-indicated removal process for each maskant to ensure there is no adhesive tape left on the aircraft. Customers utilizing BA FOD Control Boards have realized a significant reduction in FOD/Reject Tags, as well as substantial time savings.

Background and Process:

The Bron Aerotech FOD Control Board is an innovation that combines pre-cut, peel-and-place, full-size maskant decals with the Lean 5S Visual Factory Shadow Board concept.

Using a CAD tool, maskant patterns for a painting or assembly build sequence are identified. Maskant shapes and maskant placement orientations are then condensed to fit onto a neatly designed, hand-held Styrene board containing the maskants. The position of each maskant pattern on the Styrene board mimics each mask decal placement onto the structure being painted or assembled. Visual orientation notes (Forward/Aft, Inboard/Outboard, Up/Down) can be used to further assist a worker to properly place the mask patterns.

Productivity is improved by eliminating the need to hand-mask odd-shapes, and by reduction in hand-fit, tear-and-place mask work. While masking of straight edges is easily facilitated with traditional rolls of masking tape, complex shapes (including circles, 3-D surface edges, hexagons, etc.) require multiple tear-and-place operations.

However, as beneficial as pre-cut, peel-and-place mask patterns may be, the real savings come in de-masking and improved quality.

Following painting, the task of identifying all of the masked surfaces can be a nightmare as everything now appears the same-both the structure and the masking. Where did all the masking go?

Flip the Bron Aerotech FOD Control Board over to reveal the “Shadow Board” visual aid. The technician clearly knows where the maskant patterns are located on the structure thru the mimicking of the FOD Control Board design. The technician then “fills-in” the Shadow Board with the maskant patterns as he peels them off the assembly.

Quality can quickly review the post-paint Shadow Board with all shadow areas filled and approve the FOD check that follows the paint sequence.

Applications:

- Fineline Paint Masking

- FOD Mitigating

- Outdoor Paint Masking

- Painting and De-Paint Masking

- Positioning

- Quality Assurance Marking

- Spray Paint Masking

- Temporary Surface Protecting

Properties:

| Process: |

Assembly, FOD Control, Location Accuracy, Quality Inspection, Painting |

|

Adhesive: |

Various |