BA 31968 HTCRC / VDA / 50 Gauge Polyimide/ Fiberglass 116

Product details

- Type Polyimide

- Backing / Carrier Type Polyimide

- Total Thickness 5.8 mil

Datasheet Request

Request a datasheet with additional technical information through the contact form below

Worldwide Shipping

Custom Converting Capabilities

Certs + Documentation Available

AS 9100 + ISO 9001:2015 Certified through NSF-ISR

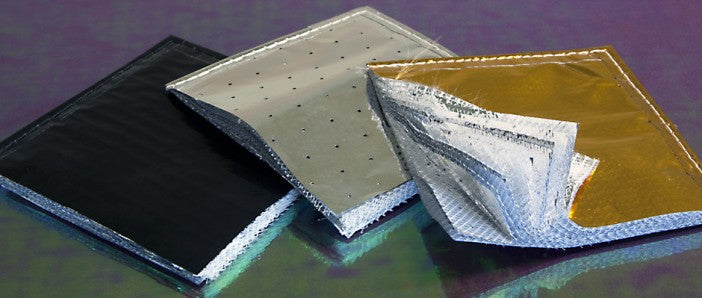

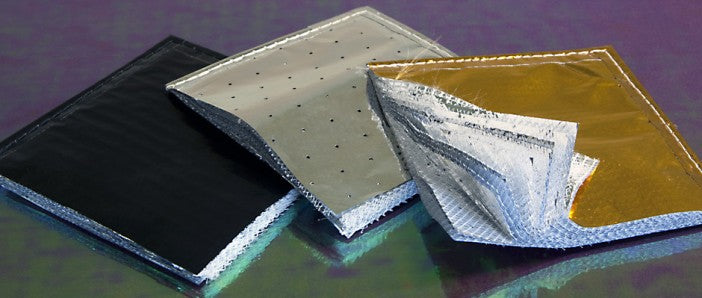

BA 31968 is a 50-gauge polyimide based product that is aluminized on one surface, coated with a corrosion resistant coating and reinforced on the other surface with a 116-glass fabric. BA 31968 is primarily used as an inner layer on an MLI blanket to resist tearing from handling or inner contact on the spacecraft bus itself how it works. BA 31968 offers excellent physical, thermal, electrical and optical properties and complies with the requirements of ASTM D-5213.

For a Technical Data Sheet, please contact us.

Applications:

- Inner Layer MLI