We focus on material application solutions for:

-International Space Station

-Space Launch Vehicles

-Human Flight Spacecraft

-Human Habitat

-Satellites

-Missiles

Our principal application categories include:

-Orbital Debris Mitigation

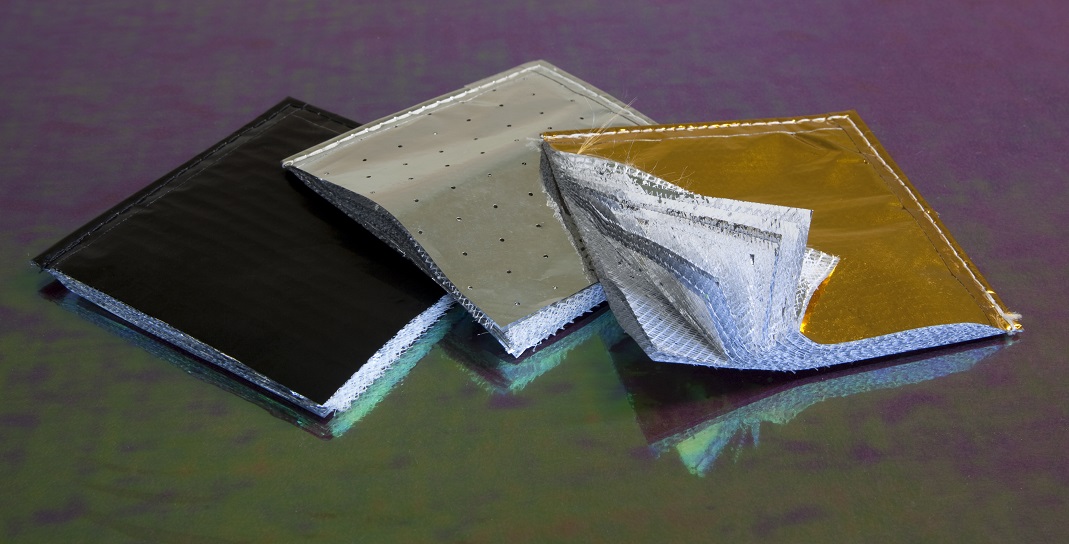

-Spacecraft Thermal Control

-AO Resistance

-Moisture/Vibration Damping

-Ablative Material Bonding

-Cryogenic Insulation

-Corrosion Control

-EMI Shielding

-ESD Control

Our Application Specialists work with your Engineers and Supply Chain to present promising candidate materials in the Qualification process. Subsequent material manufacturer modifications to these films, tapes, fabrics and other products are initiated, tracked and communicated to achieve the best solution for the application.

Space Materials

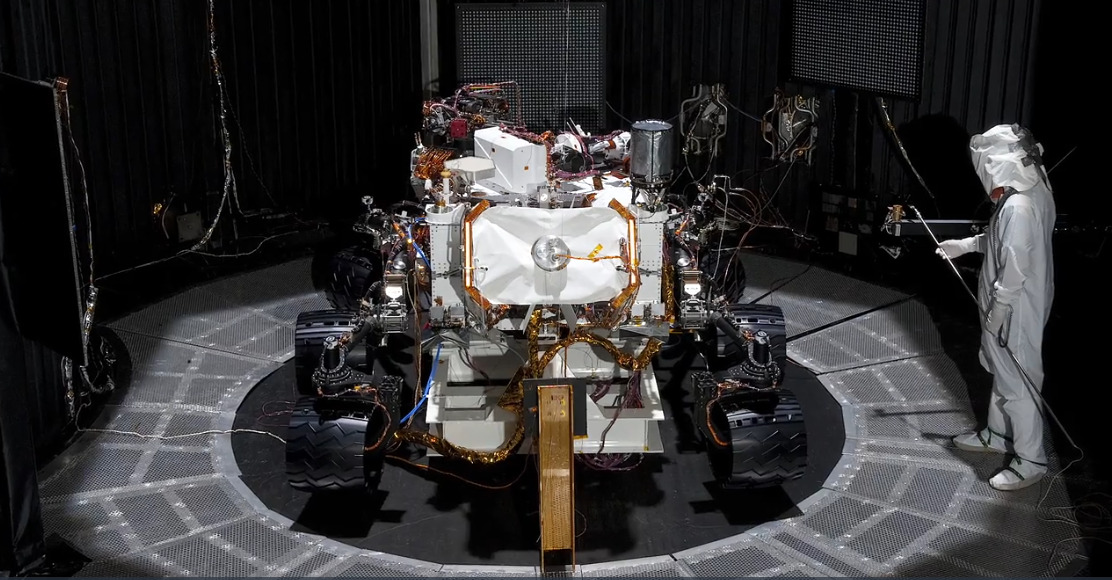

Our BA 500BC Beta Fabric sits 40 million miles away on Mars– protecting the Nuclear Power Plant on the Curiosity Rover.

Space

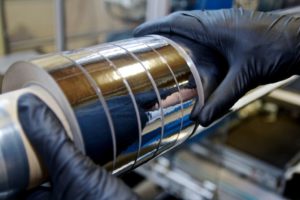

We supply space-qualified Passive Thermal Control Materials to Launch Vehicle, Habitat, and Spacecraft OEMs and their Tiers and Fabricators. We also supply flight and non-flight engineered films, fabrics, PSA tapes and adhesives, ablative cork, rubber, bonding materials, thin films and metals, and a variety of custom laminates and die-cut surface protection products.

Our materials are incorporated into a wide range of space applications including orbital debris mitigation, de-orbit technologies, vibration damping, light blocking, multi-layer insulation blankets (MLIB), flexible circuit heaters. Also wire and harness protection, emi shielding and many others.

How We Work:

Our Application Specialists team up with your Engineering, Quality and Procurement and a wide range of specialized manufacturers to ensure the best material and process solution is found.

The solution may be a material to specification, or a customized product, or even an existing industrial material that performs – and provides cost-savings. These solutions take time, but we’re in it for the long run. Our 45 years’ experience in Industrial and Aerospace materials proves it.

MLI Blanket Materials

Our Specialty Converting capability speeds the process and allows for greater flexibility and creativity in arriving at a material solution.